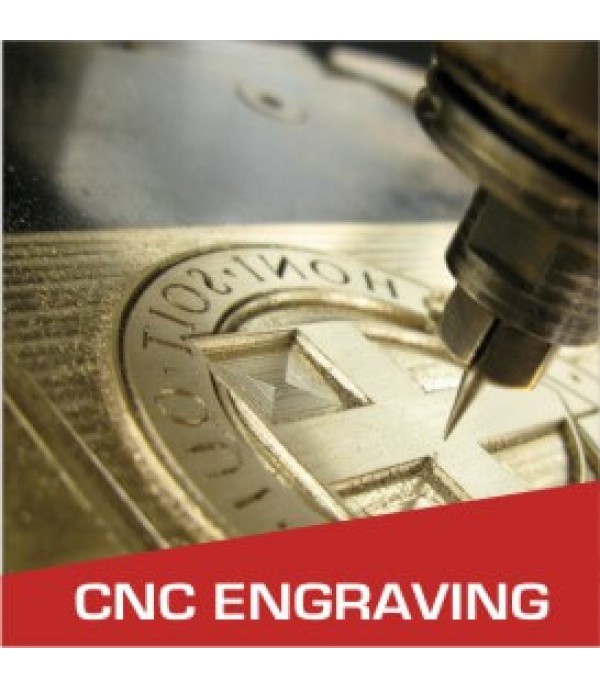

CNC Engraving

The advantage of CNC engraving is the ability to have full control of your cutting depth making this process a superior route for many applications.

High-speed spindles and specialized cutters combined with our experienced and qualified employees, enable us to achieve the effects our clients demand. We rise to every challenge presented to us.

The tooling we produce is primarily engraved into brass, aluminum, copper, magnesium or cast iron. Examples of our tooling include 3D embossing and de-bossing blocks, combination foil and embossing blocks, branding dies, mold cavity inserts, rotary cutting and hot stamp cylinders.

Brass Flat Blocks:

Brass is ideally suited because of its excellent machining ability and is an ideal substitute to copper, however owing to the manufacturing process, it is not always more cost effective. The primary advantage of brass is its ability to give a fantastic finish by holding incredibly fine detail.

3D Embossing Blocks:

3D embossing is the greatest advantage of CNC engraving in the printing industry. The ability to work on multiple levels enables CAD operators to breath life into flat images by making them literally jump out at you. In this competitive market, this technique is an incredibly valuable tool in the hands of a talented graphic designer.

Combination Foiling and embossing Blocks

This is a step up from the 3D embossing block as the ability to hot stamp foil at the same time is added to the tool. By foiling simultaneously we are able to eliminate one production process, which not only saves time but reduces costs. A further advantage is a cleaner final print by eliminating overall spoilage due to mis registration between the foiling and embossing processes. These are just a few good reasons to consider this option.